Fiber optic temperature sensor, Intelligent monitoring system, Distributed fiber optic manufacturer in China

|

|

|

In the smart grid, power transformers have become indispensable equipment. The operation of transformers directly affects people’s production and life. In order to better detect the status of transformers, it is necessary to perform controllable detection on transformers. The lifespan of a transformer mainly depends on its insulation capacity. In the actual operation of transformers, the temperature of the transformer affects its insulation capacity, so the lifespan of the transformer is inferred by detecting the temperature of the transformer. During transformer operation, the core temperature can directly reflect the internal temperature, so there is an urgent need for a detection method that can accurately detect the core temperature.

At present, there are three main methods for detecting the temperature of iron cores: thermal simulation measurement method, indirect calculation measurement method, and direct measurement method. The use of thermal simulation measurement method to measure winding temperature is widely used due to its simplicity, but the simulation process and temperature rise process have significant errors, resulting in inaccurate prediction results that cannot accurately reflect the winding temperature. The indirect calculation method for measuring winding temperature simplifies the thermal characteristic distribution of transformers, and the calculation is simple and has a certain degree of accuracy. However, the calculation results may be affected by the hot spots in the windings. The direct measurement method can accurately reflect the trend of temperature changes inside the transformer by directly measuring the winding temperature. Direct measurement methods mainly include electrical signal sensor testing, infrared temperature measurement testing, and fiber optic temperature measurement testing.

The electrical signal sensor measurement method is used to directly measure the internal temperature of transformers, but the electrical signal sensor has a short lifespan and is greatly affected by electromagnetic interference, and the test results cannot accurately reflect the internal temperature. The infrared temperature measurement method uses infrared testing, but it is susceptible to electromagnetic interference and cannot transmit the test results in a timely manner, making it impossible to achieve real-time monitoring function. The fiber optic temperature measurement method has been widely used due to its high measurement accuracy. However, when this method is applied to transformer temperature measurement, fiber optic sensors can only be placed based on experience, resulting in problems such as a small number of temperature measurement points and uneven distribution of temperature measurement points.

This paper proposes a transformer coil core temperature monitoring method based on fiber optic grating sensors to address the problems of limited number of temperature measurement points, uneven distribution of test points, and inability to transmit measurement results in real-time in current direct measurement methods. This method can improve the current level of internal temperature detection in transformers, increase the service life of transformers, and reduce the failure rate of transformers.

1. Principles of grating sensors

Fiber Grating Sensor is a wavelength modulated fiber optic sensor that obtains sensing information by modulating the fiber Bragg wavelength with external physical parameters. Fiber optic grating sensors have advantages such as anti electromagnetic interference, good electrical insulation performance, small size, and low transmission loss.

Fiber Bragg gratings have thermal optical and thermal expansion effects, which will directly affect the temperature characteristics of fiber Bragg gratings. When the thermal optical effect occurs in the fiber optic grating, the effective refractive index of the corresponding grating will change. If the grating period changes, it indicates that the fiber optic grating has undergone thermal expansion effect. If the temperature and Bragg wavelength change, it indicates that both the thermal optical effect and thermal expansion effect are generated on the fiber optic grating.

Fiber Bragg Grating can not only measure temperature, but also strain. The strain characteristics of fiber Bragg gratings are mainly affected by elastic and elasto optical effects. The elastic effect has a significant impact on the grating period of fiber Bragg gratings, while the elastic optical effect changes the effective refractive index of fiber Bragg grating sensors.

2 Design Methods

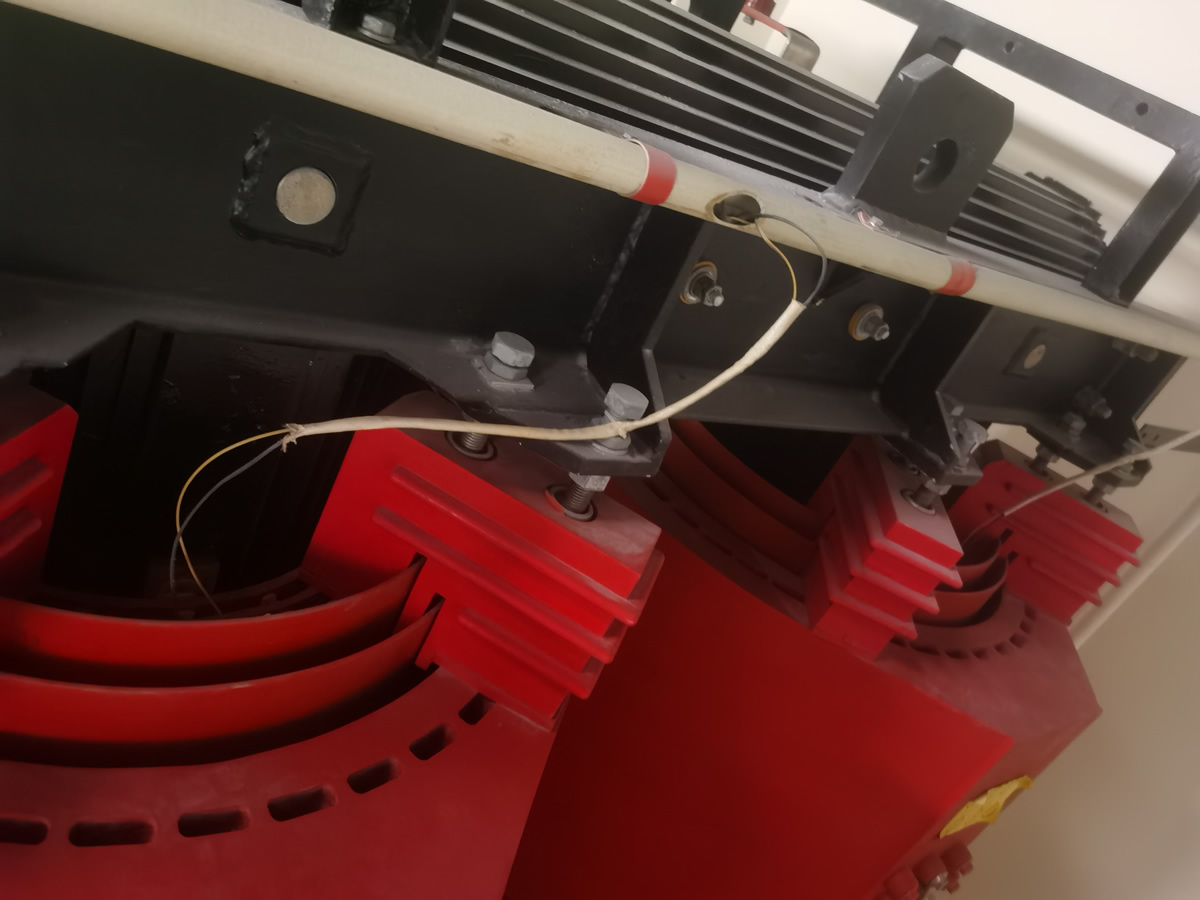

The iron core temperature monitoring system based on fiber optic grating sensors is mainly divided into sensor embedded transformers, temperature detection systems, and sensor transmission systems.

2.1 Temperature detection system

Traditional temperature detection has problems such as difficulty in temperature measurement, limited measurement points, and weak anti-interference ability of testing methods. Therefore, this study proposes a method of embedding fiber optic grating sensors into transformer cores, collecting temperature data through fiber optic grating sensors and transmitting the collected signals. Due to the small size and strong anti-interference ability of fiber optic grating sensors, they can work normally in high temperature and high pressure environments, so they can be fully embedded inside transformers. Firstly, the fiber optic grating is pre stretched using a fiber optic pre stretching tool, and then the operated fiber is gold-plated. Due to the temperature and strain characteristics of fiber optic grating sensors, in order to improve the measurement accuracy of fiber optic grating sensors, it is necessary to reduce the influence of strain characteristics and improve the thermal expansion coefficient to enhance sensitivity. Due to the high thermal expansion coefficient of aluminum alloy, the measurement performance of fiber optic grating sensors can be improved by combining them with the aluminum alloy substrate of the iron core through rigid welding technology. Use tools to perform slotting work on the back of the iron core, with a moderate size that does not affect the normal operation of the iron core. During the process of wrapping copper flat wire with paper, a guiding device is used to guide the optical fiber into the small groove opened by the copper flat wire, while reserving the fiber tail fiber for leading out sensing signals.

2.2 Sensor transmission system

This study adopts wavelength division multiplexing technology and space division multiplexing technology. Wavelength division multiplexing technology is the transmission of two or more signals through different channels on a single optical fiber, without affecting each other. This transmission method allows optical fibers to transmit more information. Space division multiplexing technology combines multiple optical fibers to form multiple channels, each of which is independent of each other, and the signal is transmitted on the corresponding channel. By adopting wavelength division multiplexing technology and space division multiplexing technology, limited optical fibers can be maximally transmitted information, effectively solving the problem of fewer internal temperature measurement points in transformers. Firstly, detection data is collected through fiber optic grating sensors, and then transmitted to a demodulator. The demodulator converts the wavelength signal into a digital signal, and the computer receives the signal and displays real-time detection results.

To solve the problem of difficult temperature measurement and few temperature measurement points in transformers, this paper proposes a temperature monitoring method for transformer coil iron core based on fiber optic grating sensors. Embed the fiber optic grating sensor into the transformer core, and use space division multiplexing and wavelength division multiplexing methods to transmit the sensor information to the demodulator. The demodulator converts the wavelength signal into digital information and transmits it to the computer to achieve real-time monitoring function. The simulation results show that compared with the ESSM measurement method, ITM measurement method, and FOTM temperature measurement method, the FGCTM measurement method proposed in this paper can effectively improve the detection accuracy of internal temperature in transformers. Due to its advantages such as small size, strong resistance to electromagnetic interference, and good insulation, fiber optic grating sensors can continuously achieve real-time temperature monitoring of high sealing and high-voltage equipment, making them suitable for other temperature detection applications.

INNO fibre optic temperature sensors ,temperature monitoring systems.

INNO fibre optic temperature sensors ,temperature monitoring systems.