- Fluorescence fiber optic sensors provide ±0.5°C accuracy for switchgear components without electromagnetic interference

- Optical temperature measurement eliminates electrical connections that could compromise switchgear safety and performance

- Advanced fiber optic systems monitor critical temperatures in real-time across all switchgear components simultaneously

- Intrinsically safe sensors enable monitoring in high-voltage environments without creating additional electrical hazards

- Multi-point fiber optic networks create comprehensive thermal maps of entire switchgear installations

- Fluorescence technology operates reliably in extreme electromagnetic fields present in modern switchgear systems

- Long-term stability ensures consistent monitoring performance over 20+ years without calibration drift

Modern electrical switchgear systems demand sophisticated temperature monitoring solutions that can operate reliably in challenging electromagnetic environments while providing accurate thermal data for optimal performance and safety. Switchgear components fiber optic temperature measurement represents the most advanced approach to thermal surveillance, utilizing fluorescence technology to deliver precision monitoring without the limitations of traditional electrical sensors.

The evolution of switchgear design toward higher voltages, increased power densities, and more compact configurations has created new challenges for temperature monitoring systems. Traditional electrical sensors struggle with electromagnetic interference, safety concerns, and installation complexity in these demanding applications. Fiber optic temperature measurement technology addresses these challenges through its fundamental optical measurement principles that provide complete immunity to electrical interference while maintaining exceptional accuracy and reliability.

| Monitoring Technology | ความถูกต้อง | EMI Immunity | Safety Level | Installation Complexity | Maintenance Requirements |

|---|---|---|---|---|---|

| Fluorescence Fiber Optic | ±0.5°C | Complete | Intrinsically Safe | Simple | Minimal |

| RTD Sensors | ±1.0°C | Poor | Electrical Hazard | Complex | Regular |

| Thermocouple | ±2.0°C | Fair | Moderate Risk | Moderate | Frequent |

| Infrared Thermal | ±3.0°C | Excellent | No Contact | Complex Setup | Regular Calibration |

What Are High-Temperature Optical Fiber Solutions for Switchgear Applications?

High-temperature optical fiber solutions for switchgear applications utilize advanced materials and design principles to provide reliable temperature monitoring in extreme thermal environments. These systems employ specialized optical fibers and sensor technologies that maintain measurement accuracy and structural integrity at temperatures exceeding 250°C while withstanding the harsh electrical environments typical of switchgear installations.

Advanced fiber optic solutions incorporate sapphire-based sensing elements and high-temperature optical fibers that resist thermal degradation and electromagnetic interference. The sensing principle relies on fluorescence decay time analysis of rare earth phosphor materials whose optical properties change predictably with temperature, enabling precise measurement through quantum physics principles that remain stable regardless of electrical field strength or electromagnetic noise.

Material Science Innovations

Modern high-temperature optical fiber solutions utilize crystalline sapphire sensing tips and specialized fluorescence materials optimized for extreme thermal conditions. These materials maintain stable optical properties across wide temperature ranges while resisting chemical attack and mechanical stress. The crystalline structure provides exceptional durability that enables long-term operation in switchgear environments without performance degradation.

Optical fiber construction employs high-purity silica cores with specialized coatings that maintain signal transmission integrity at elevated temperatures. Advanced jacketing materials protect fibers from mechanical damage and chemical exposure while maintaining flexibility for installation in confined switchgear spaces.

| Component | Material | Temperature Range | Key Properties | Durability |

|---|---|---|---|---|

| Sensing Tip | Sapphire Crystal | -200°C to +250°C | Chemical resistance, mechanical strength | 20+ ปี |

| Phosphor Material | Rare Earth Compounds | -100°C to +200°C | Stable fluorescence, quantum efficiency | 15+ ปี |

| Optical Fiber | High-purity Silica | -50°C to +300°C | Low attenuation, high bandwidth | 25+ ปี |

| Protective Jacket | Fluoropolymer | -40°C to +200°C | Chemical resistance, flexibility | 10+ ปี |

How Do Wafer Sensors Enhance Semiconductor Temperature Control?

Wafer sensors enhance semiconductor temperature control through precise, non-contact monitoring that maintains semiconductor fabrication process integrity while providing real-time thermal feedback. These specialized sensors utilize fiber optic technology to monitor wafer temperatures during critical processing steps without introducing contamination or electromagnetic interference that could affect sensitive semiconductor manufacturing operations.

Advanced wafer sensor systems employ miniaturized fiber optic probes that can be positioned close to semiconductor wafers without physical contact, eliminating contamination risks while providing accurate temperature measurement. The optical measurement principle ensures complete electrical isolation that prevents interference with sensitive semiconductor processing equipment and maintains clean room environment standards.

Semiconductor Process Integration

Fiber optic wafer sensors integrate seamlessly with semiconductor processing equipment through specialized feedthroughs and mounting systems designed for clean room environments. Multi-point monitoring capabilities enable simultaneous temperature measurement across wafer surfaces, providing comprehensive thermal mapping essential for process optimization and quality control.

Real-time temperature data from wafer sensors enables closed-loop control of heating and cooling systems that maintain precise thermal conditions throughout semiconductor processing cycles. This precise control improves product yield and reduces defects caused by thermal variations during critical manufacturing steps.

Why Is Thermal Monitoring Critical for Electrical System Performance?

Thermal monitoring is critical for electrical system performance because temperature directly affects electrical conductivity, insulation integrity, and component reliability throughout switchgear systems. Excessive temperatures accelerate aging processes, reduce insulation life, and increase failure rates while optimal thermal management extends equipment life and improves system reliability.

Advanced thermal monitoring enables proactive maintenance strategies that address developing problems before they cause equipment failures or safety hazards. Real-time temperature data supports dynamic loading decisions that optimize equipment utilization while maintaining safe operating margins, maximizing both performance and longevity of electrical systems.

Thermal Impact on Electrical Components

Electrical components experience exponential degradation rates as temperatures exceed design limits, with insulation life halving for every 8-10°C temperature increase above rated conditions. Contact resistance increases with temperature, causing additional heating and potential failure cascades that can affect entire switchgear installations.

Thermal cycling creates mechanical stress that can cause connection loosening and insulation cracking over time. Comprehensive thermal monitoring identifies these developing problems early, enabling preventive maintenance that avoids costly failures and unplanned outages.

What Information Do Electrical Switchgear Diagrams Provide for Temperature Monitoring?

Electrical switchgear diagrams provide essential information for temperature monitoring including component locations, thermal load distributions, cooling system layouts, and critical measurement points that guide sensor placement and monitoring system design. These diagrams identify high-risk thermal areas and optimal sensor positions for comprehensive temperature surveillance.

Switchgear diagrams also indicate electrical connections, current paths, and potential electromagnetic interference sources that affect monitoring system design and installation. Understanding circuit topology enables optimal routing of fiber optic cables and placement of monitoring equipment to minimize interference and maximize measurement accuracy.

Strategic Monitoring Point Identification

Electrical switchgear diagrams reveal critical monitoring points including bus connections, circuit breaker contacts, transformer terminals, and cable terminations where thermal problems typically develop. Strategic sensor placement at these locations provides early warning of developing problems before they affect system performance.

Thermal modeling based on switchgear diagrams enables optimization of monitoring strategies that provide comprehensive coverage while minimizing sensor count and installation complexity. This analytical approach ensures maximum protection efficiency and cost-effectiveness.

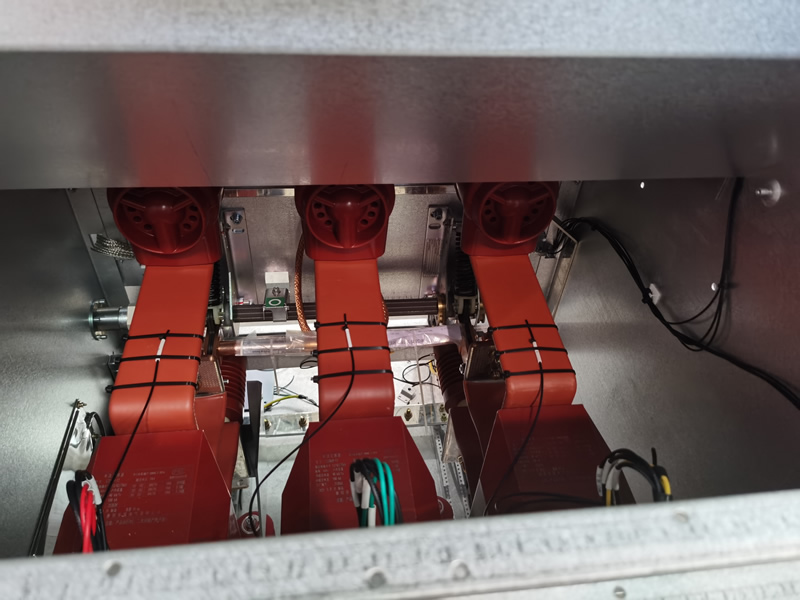

Which Switchgear Components Require Priority Temperature Monitoring?

Switchgear components requiring priority temperature monitoring include circuit breaker contacts, bus connections, cable terminations, transformer bushings, and disconnect switch contacts where high current densities and mechanical stress create elevated thermal risks. These components experience the highest failure rates and greatest safety hazards when thermal problems develop.

Secondary monitoring priorities include control circuits, auxiliary equipment, and environmental systems that support primary switchgear functions. Comprehensive monitoring strategies address both primary and secondary components to ensure complete system reliability and optimal performance under all operating conditions.

| Component Type | Thermal Risk Level | Failure Impact | Monitoring Priority | Recommended Sensors |

|---|---|---|---|---|

| Circuit Breaker Contacts | Very High | System Outage | Critical | 2-4 per breaker |

| Bus Connections | สูง | Multiple Feeders | สูง | 1-2 per connection |

| Cable Terminations | สูง | Feeder Loss | สูง | 1 per termination |

| Transformer Bushings | Moderate | Transformer Loss | Moderate | 1 per bushing |

| Control Circuits | Low | Control Loss | Low | 1 per panel |

How Do MRI Monitors Utilize Fiber Optic Temperature Measurement?

MRI monitors utilize fiber optic temperature measurement to provide patient and equipment temperature monitoring in strong magnetic field environments where traditional electrical sensors cannot function. Fiber optic sensors offer complete magnetic field immunity that enables accurate temperature measurement without affecting MRI system performance or image quality.

Advanced MRI monitoring systems employ fluorescence fiber optic sensors for patient body temperature monitoring during extended procedures and equipment thermal management in high-field magnetic environments. The non-magnetic properties of optical sensors eliminate safety risks and measurement artifacts associated with electrical sensors in MRI applications.

Magnetic Field Immunity Advantages

Fiber optic temperature sensors maintain measurement accuracy regardless of magnetic field strength or gradient variations that characterize MRI environments. Complete absence of magnetic materials in sensor construction eliminates field distortion and safety hazards while providing reliable temperature data throughout MRI procedures.

Multi-point monitoring capabilities enable simultaneous temperature surveillance of multiple patients and equipment components without electromagnetic interference or safety concerns. This comprehensive monitoring improves patient safety and equipment reliability in demanding MRI environments.

What Are Fiber Optic Sensor Systems and Their Applications in Switchgear?

Fiber optic sensor systems for switchgear applications comprise networks of optical sensors, signal processing electronics, and communication systems that provide comprehensive temperature monitoring across electrical installations. These systems utilize wavelength division multiplexing and advanced signal processing to monitor multiple measurement points through single fiber optic cables.

Advanced fiber optic sensor systems integrate with SCADA and control systems to provide real-time temperature data for operational decision-making and automated protection functions. Distributed sensing capabilities enable monitoring of hundreds of measurement points through unified platforms that simplify installation and reduce maintenance requirements.

System Architecture and Integration

Modern fiber optic sensor systems employ distributed architectures that combine point sensors, การตรวจจับอุณหภูมิแบบกระจาย, and hybrid approaches to optimize monitoring coverage and cost-effectiveness. Intelligent signal processing algorithms analyze temperature patterns to identify developing problems and provide predictive maintenance insights.

Integration capabilities include standard industrial communication protocols, alarm management systems, and data analytics platforms that transform temperature monitoring data into actionable intelligence for maintenance and operational optimization.

How Is MR Temperature Monitored in Medical Applications?

MR temperature monitoring in medical applications utilizes specialized fiber optic sensors designed for magnetic resonance environments where traditional electrical monitoring systems cannot operate safely or effectively. These systems provide real-time temperature monitoring for patient safety and equipment protection during MRI procedures.

Advanced MR temperature monitoring employs multiple sensor configurations including surface sensors for skin temperature monitoring and probe sensors for internal temperature measurement during interventional procedures. Fiber optic technology ensures complete magnetic field immunity while maintaining the precision required for medical applications.

Patient Safety and Clinical Benefits

Fiber optic MR temperature monitoring enhances patient safety by providing continuous thermal surveillance without electromagnetic interference or safety hazards. Real-time temperature data enables immediate response to thermal emergencies and optimization of treatment protocols based on thermal response patterns.

Clinical applications include hyperthermia treatment monitoring, cryotherapy temperature control, and general patient thermal management during extended MRI procedures. Precise temperature control improves treatment effectiveness while ensuring patient safety throughout medical procedures.

What Is GB3 Application in Temperature Monitoring Systems?

GB3 application in temperature monitoring systems refers to specialized protocols and standards for industrial temperature measurement that ensure reliability, ความถูกต้อง, and safety in critical applications. GB3 standards establish requirements for sensor performance, data transmission, and system integration that support optimal monitoring effectiveness.

GB3 compliant temperature monitoring systems incorporate redundancy, การตรวจจับข้อผิดพลาด, and diagnostic capabilities that ensure continuous operation and accurate measurement under all conditions. These systems meet stringent industrial requirements for reliability and performance in safety-critical applications.

Standards Compliance and Certification

GB3 application standards require comprehensive testing and validation of temperature monitoring systems to ensure they meet specified performance criteria under all operating conditions. Certification processes verify sensor accuracy, system reliability, and communication integrity throughout operational lifetime.

Compliance with GB3 standards demonstrates system suitability for critical applications where temperature monitoring failures could result in safety hazards or significant economic losses. Standard compliance provides confidence in system performance and regulatory acceptance.

How Do Wafer Temperature Measurement Systems Enhance Semiconductor Manufacturing?

Wafer temperature measurement systems enhance semiconductor manufacturing by providing precise thermal control during critical processing steps that determine product quality and yield. Advanced fiber optic systems enable non-contact temperature monitoring that maintains clean room standards while providing real-time thermal feedback for process optimization.

Sophisticated wafer temperature measurement incorporates multi-point sensing and thermal mapping capabilities that reveal temperature variations across wafer surfaces. This detailed thermal information enables process adjustments that improve uniformity and reduce defects in semiconductor manufacturing operations.

Process Optimization Benefits

Real-time wafer temperature measurement enables closed-loop process control that maintains optimal thermal conditions throughout manufacturing cycles. Precise temperature control improves crystal growth, doping uniformity, and metallization quality that directly affect semiconductor device performance and reliability.

Advanced measurement systems provide thermal history data that enables correlation analysis between temperature profiles and product quality metrics. This analytical capability supports continuous process improvement and yield optimization in semiconductor manufacturing.

Why Are Fiber Optic Temperature Measurement Systems Superior for Electrical Applications?

Fiber optic temperature measurement systems are superior for electrical applications because they provide complete electromagnetic immunity, ความปลอดภัยที่แท้จริง, and exceptional accuracy without introducing electrical hazards or interference concerns. These fundamental advantages make optical measurement ideal for high-voltage and high-current electrical environments.

Advanced fiber optic systems offer long-term stability and reliability that exceeds traditional electrical sensors while requiring minimal maintenance and calibration. Multi-point monitoring capabilities enable comprehensive thermal surveillance through simplified installation and reduced system complexity.

| Performance Factor | Fiber Optic Systems | Traditional Electrical | Advantage Ratio |

|---|---|---|---|

| ความถูกต้อง | ±0.5°C | ±1-2°C | 2-4x better |

| EMI Immunity | Complete | Limited | 100% improvement |

| Safety Level | Intrinsically Safe | Electrical Hazard | Infinite improvement |

| Maintenance Interval | 10+ ปี | 1-2 ปี | 5-10x longer |

| Installation Complexity | Simple | Complex | 50-75% reduction |

How Do Winding Sensors Optimize Electric Motor and Transformer Performance?

Winding sensors optimize electric motor and transformer performance by providing real-time temperature monitoring of conductors and insulation systems that enables precise thermal management and load optimization. Direct winding temperature measurement eliminates estimation errors and provides accurate data for performance optimization and protection.

Advanced winding sensor systems employ fiber optic technology to monitor multiple points within windings without affecting electrical performance or creating safety hazards. Multi-point monitoring reveals thermal gradients and hot spots that enable optimal cooling system operation and load distribution for maximum equipment utilization.

Performance Optimization Strategies

Real-time winding temperature data enables dynamic loading strategies that maximize equipment utilization while maintaining safe thermal margins. Temperature-based control algorithms optimize cooling system operation and load scheduling to extend equipment life and improve energy efficiency.

Predictive maintenance programs utilize winding temperature trends to identify developing problems before they affect performance or reliability. Early problem detection enables proactive maintenance that prevents failures and optimizes equipment availability.

What Semiconductor Temperature Control Methods Utilize Fiber Optic Monitoring?

Semiconductor temperature control methods utilizing fiber optic monitoring include wafer processing temperature control, equipment thermal management, and clean room environmental monitoring that maintain optimal conditions for semiconductor manufacturing. Fiber optic sensors provide contamination-free monitoring that meets stringent clean room requirements.

Advanced semiconductor temperature control incorporates real-time feedback loops that utilize fiber optic sensor data to optimize heating and cooling systems throughout manufacturing processes. Precise temperature control improves product quality and reduces defects while maintaining productivity and yield targets.

Clean Room Environment Advantages

Fiber optic temperature monitoring eliminates contamination sources and electromagnetic interference that could affect sensitive semiconductor manufacturing processes. Non-contact measurement capabilities maintain clean room standards while providing accurate thermal data for process optimization.

Multi-point monitoring enables comprehensive temperature mapping of processing equipment and clean room environments that supports optimal conditions for semiconductor manufacturing. Detailed thermal information guides facility design and equipment operation for maximum manufacturing effectiveness.

How Do Devices Responsive to Ambient Temperature Conditions Enhance System Performance?

Devices responsive to ambient temperature conditions enhance system performance by providing environmental compensation that maintains optimal operating conditions regardless of external temperature variations. These systems automatically adjust operating parameters based on ambient conditions to optimize performance and efficiency.

Advanced ambient temperature responsive devices utilize fiber optic sensors to monitor environmental conditions and equipment temperatures simultaneously, enabling comprehensive thermal management that considers both internal heat generation and external thermal influences on system performance.

Adaptive Control Systems

Ambient temperature responsive systems employ adaptive control algorithms that automatically adjust cooling, heating, and operational parameters based on environmental conditions. This automatic adaptation maintains optimal performance while minimizing energy consumption and equipment stress.

Predictive capabilities enable these systems to anticipate thermal changes and proactively adjust operating conditions before temperature variations affect performance. This forward-looking approach maintains consistent operation and prevents thermal-related performance degradation.

What Role Does Hot Spot Monitoring Play in Electrical Equipment Safety?

Hot spot monitoring plays a critical role in electrical equipment safety by detecting localized overheating that often precedes failures and safety hazards. Early detection of hot spots enables preventive actions that eliminate safety risks while maintaining equipment reliability and performance.

Advanced hot spot monitoring systems utilize fiber optic sensors strategically placed at high-risk locations to provide continuous thermal surveillance without creating additional electrical hazards. Multi-point monitoring creates comprehensive thermal maps that reveal developing problems before they become dangerous.

Safety Risk Mitigation

Hot spot monitoring enables early identification of thermal problems that could lead to equipment failures, fires, or other safety hazards. Immediate detection capabilities provide adequate warning time for corrective actions that eliminate safety risks and prevent accidents.

Automated alarm systems provide immediate notification of dangerous thermal conditions while integration with protection systems enables automatic responses that maintain safety even when human operators are unavailable or distracted.

How Does Semiconductor Process Control Benefit from Fiber Optic Temperature Monitoring?

Semiconductor process control benefits from fiber optic temperature monitoring through precise, contamination-free thermal measurement that maintains process integrity while providing real-time feedback for optimization. Optical sensors eliminate electromagnetic interference and contamination risks that could affect sensitive semiconductor manufacturing operations.

Advanced process control systems integrate fiber optic temperature data with other process parameters to enable comprehensive optimization that improves product quality and manufacturing efficiency. Real-time thermal feedback enables immediate process adjustments that maintain optimal conditions throughout manufacturing cycles.

Quality and Yield Improvements

Precise temperature control enabled by fiber optic monitoring improves semiconductor device quality by maintaining optimal thermal conditions during critical processing steps. Temperature uniformity across wafers reduces defects and improves yield rates while consistent thermal control enhances device performance characteristics.

Statistical process control utilizing temperature data enables continuous improvement programs that optimize manufacturing processes based on thermal performance correlations. Data-driven optimization reduces variability and improves manufacturing consistency.

What Are Electrical Switchgear Components and Their Temperature Monitoring Requirements?

Electrical switchgear components include circuit breakers, disconnect switches, bus systems, protective relays, control circuits, and auxiliary equipment that require specialized temperature monitoring to ensure safe and reliable operation. Each component type has specific thermal characteristics and monitoring requirements based on its function and failure modes.

Temperature monitoring requirements vary by component type, with high-current devices requiring more intensive monitoring due to resistive heating and contact degradation risks. Comprehensive monitoring strategies address all critical components while optimizing sensor placement and system complexity for cost-effective implementation.

| Switchgear Component | Temperature Range | Monitoring Criticality | Failure Consequences | Sensor Requirements |

|---|---|---|---|---|

| Circuit Breaker | 20-150°C | Critical | System Protection Loss | Multiple contact points |

| Bus System | 20-120°C | สูง | Multiple Circuit Loss | Connection monitoring |

| Disconnect Switch | 20-130°C | สูง | Isolation Failure | Contact temperature |

| Control Circuits | 20-80°C | Moderate | Control Function Loss | General monitoring |

| Auxiliary Equipment | 20-70°C | Low | Support Function Loss | Environmental monitoring |

How Do Semiconductor Temperature Sensors Enhance Manufacturing Process Control?

Semiconductor temperature sensors enhance manufacturing process control by providing precise thermal measurement that enables optimal process conditions and improved product quality. Advanced sensors utilize fiber optic technology to provide contamination-free monitoring that meets stringent clean room requirements while maintaining measurement accuracy.

Manufacturing process control systems integrate temperature sensor data with other process parameters to enable comprehensive optimization that improves yield rates and product consistency. Real-time thermal feedback enables immediate process adjustments that maintain optimal conditions throughout production cycles.

Integration with Manufacturing Systems

Semiconductor temperature sensors integrate with manufacturing execution systems and process control platforms to provide comprehensive thermal management throughout production facilities. Advanced integration enables automated responses to thermal variations that maintain optimal manufacturing conditions.

Data analytics platforms utilize temperature sensor information to identify process optimization opportunities and predict equipment maintenance needs. Predictive capabilities enable proactive maintenance that prevents thermal-related production disruptions.

Why Is Transformer Temperature Monitoring Essential for Power System Reliability?

Transformer temperature monitoring is essential for power system reliability because thermal stress is the primary factor affecting transformer life and failure rates. Continuous temperature surveillance enables optimal loading strategies and preventive maintenance that maximize equipment reliability while preventing costly failures.

Advanced transformer temperature monitoring systems utilize fiber optic sensors for direct winding temperature measurement that provides accurate thermal data without electromagnetic interference or safety concerns. Multi-point monitoring enables comprehensive thermal assessment and optimal equipment utilization.

Reliability Enhancement Benefits

Temperature monitoring enables condition-based maintenance strategies that address developing problems before they affect transformer reliability. Early problem detection prevents failures while optimal thermal management extends equipment life and improves power system performance.

Dynamic loading capabilities enabled by accurate temperature monitoring allow utilities to maximize transformer utilization during peak demand periods while maintaining acceptable reliability levels. This optimization improves grid efficiency and reduces infrastructure costs.

How Do Fluorescence Sensors Provide Superior Temperature Measurement?

Fluorescence sensors provide superior temperature measurement through quantum physics principles that offer inherent accuracy and stability advantages over traditional measurement methods. Fluorescence decay time analysis enables precise temperature calculation that remains stable regardless of electromagnetic interference or environmental conditions.

Advanced fluorescence sensor technology utilizes rare earth phosphor materials whose optical properties change predictably with temperature, enabling measurement precision that exceeds electrical sensors while maintaining long-term calibration stability. These sensors operate reliably in extreme environments where traditional sensors fail.

Quantum Physics Measurement Principles

Fluorescence temperature measurement relies on excited state lifetime analysis of phosphor materials that follows well-understood quantum mechanical principles. Temperature-dependent decay characteristics enable precise measurement through timing analysis that provides inherent immunity to electromagnetic interference.

Self-referencing measurement principles eliminate calibration drift and provide absolute temperature measurement that maintains accuracy throughout sensor lifetime. This fundamental advantage reduces maintenance requirements while improving measurement reliability.

What Are Optics Transformers and Their Temperature Monitoring Applications?

Optics transformers refer to specialized optical systems that enable fiber optic sensor integration with electrical transformers for comprehensive temperature monitoring. These systems provide electrical isolation and signal conditioning that enables safe monitoring of high-voltage equipment through optical measurement principles.

Advanced optics transformers incorporate wavelength division multiplexing and signal processing capabilities that enable multiple sensor monitoring through single fiber optic connections. This approach simplifies installation while providing comprehensive temperature surveillance across entire transformer installations.

High-Voltage Application Benefits

Optics transformers enable safe monitoring of high-voltage electrical equipment by providing complete electrical isolation between sensors and monitoring electronics. This isolation eliminates safety hazards while enabling accurate temperature measurement in dangerous electrical environments.

Signal processing capabilities within optics transformers enable real-time temperature calculation and data transmission that supports immediate response to thermal problems. Advanced processing provides enhanced accuracy and diagnostic capabilities for optimal transformer management.

How Do Fiber Optic Feedthroughs Enable Safe Temperature Monitoring?

Fiber optic feedthroughs enable safe temperature monitoring by providing sealed connections that maintain environmental isolation while allowing optical signal transmission between hazardous and safe areas. These specialized connectors ensure monitoring system integrity while preventing contamination or safety hazards.

Advanced feedthrough designs incorporate high-pressure sealing and electrical isolation that enable monitoring in extreme environments including high-voltage electrical equipment, pressure vessels, and explosive atmospheres. Robust construction ensures long-term reliability and safety.

Environmental Protection and Safety

Fiber optic feedthroughs provide complete environmental sealing that prevents contamination while maintaining optical signal transmission integrity. This protection enables monitoring in hostile environments where traditional electrical feedthroughs would create safety hazards or reliability problems.

Safety certification for hazardous area applications ensures feedthroughs meet stringent requirements for explosive atmosphere monitoring. Certified feedthroughs enable monitoring in oil and gas facilities, โรงงานเคมี, and other dangerous environments.

What Are Fiber Optic Temperature Sensors and Their Advantages in Electrical Systems?

Fiber optic temperature sensors are optical measurement devices that utilize light transmission through fiber optic cables to measure temperature without electrical connections at sensor locations. These sensors provide complete electromagnetic immunity and intrinsic safety that makes them ideal for electrical system monitoring applications.

Advanced fiber optic temperature sensors employ various measurement principles including fluorescence decay, Bragg grating wavelength shift, and distributed sensing technologies that enable precise temperature measurement in challenging electrical environments. Multi-point monitoring capabilities provide comprehensive thermal surveillance through simplified installation.

| Sensor Type | Measurement Principle | ความถูกต้อง | Response Time | Distance Capability |

|---|---|---|---|---|

| Fluorescence | Decay time analysis | ±0.5°C | 1 second | 10 km+ |

| ตะแกรงไฟเบอร์แบรกก์ | Wavelength shift | ±1.0°C | 0.1 second | 100 km+ |

| Distributed Raman | Backscatter analysis | ±2.0°C | 10 วินาที | 50 km+ |

| Distributed Brillouin | Frequency shift | ±3.0°C | 60 วินาที | 200 km+ |

How Does High Voltage Switchgear Condition Monitoring Benefit from Fiber Optic Systems?

High voltage switchgear condition monitoring benefits from fiber optic systems through complete electrical isolation that enables safe monitoring of dangerous electrical equipment without creating additional safety hazards or interference concerns. Optical measurement principles provide accurate data while maintaining personnel safety and equipment integrity.

Advanced fiber optic monitoring systems provide comprehensive surveillance of switchgear components including temperature, การปลดปล่อยบางส่วน, and mechanical condition monitoring through unified platforms. Multi-parameter monitoring enables complete condition assessment that supports optimal maintenance and operational strategies.

Safety and Performance Benefits

Fiber optic switchgear monitoring eliminates electrical connections that could create arc flash hazards or equipment failures while providing continuous condition surveillance. Complete electromagnetic immunity ensures accurate measurement regardless of electrical field strength or switching transients.

Predictive maintenance capabilities enabled by comprehensive monitoring reduce unplanned outages while extending equipment life through optimal maintenance timing. Early problem detection prevents failures that could cause safety hazards or system disruptions.

What Role Do Transformer Monitors Play in Power System Management?

Transformer monitors play critical roles in power system management by providing real-time condition assessment that enables optimal loading strategies, preventive maintenance scheduling, and failure prevention. Comprehensive monitoring supports maximum equipment utilization while maintaining acceptable risk levels.

Advanced transformer monitoring systems integrate temperature measurement with dissolved gas analysis, partial discharge monitoring, and other diagnostic techniques to provide complete condition assessment. Multi-parameter monitoring enables accurate diagnosis and optimal maintenance decision-making.

Grid Optimization and Reliability

Transformer monitoring enables dynamic loading strategies that optimize grid utilization based on real-time equipment condition rather than conservative static ratings. This optimization improves grid efficiency while maintaining equipment reliability and safety.

Predictive maintenance programs utilizing monitoring data reduce maintenance costs while improving equipment availability. Condition-based maintenance strategies optimize resource allocation while preventing unexpected failures that could affect grid reliability.

How Do Fiber Optic Transducers Enable Advanced Temperature Monitoring?

Fiber optic transducers enable advanced temperature monitoring by converting thermal energy into optical signals that can be transmitted over long distances without signal degradation or electromagnetic interference. These devices provide the interface between physical temperature and optical measurement systems.

Advanced transducer designs incorporate signal processing and wavelength division multiplexing capabilities that enable multiple sensor monitoring through single fiber connections. Intelligent transducers provide enhanced measurement capabilities including self-diagnosis and automatic calibration functions.

Signal Processing and Communication

Fiber optic transducers incorporate sophisticated signal processing algorithms that extract temperature information from optical signals while filtering noise and compensating for environmental effects. Advanced processing provides enhanced accuracy and diagnostic capabilities.

Communication capabilities enable integration with industrial control systems and data analytics platforms that transform temperature measurements into actionable intelligence for maintenance and operational optimization.

What Are Optical Fiber Sensors and Their Industrial Applications?

Optical fiber sensors are measurement devices that utilize light transmission through optical fibers to monitor various physical parameters including temperature, ความดัน, strain, and vibration in industrial applications. These sensors provide unique advantages including electromagnetic immunity, ความปลอดภัยที่แท้จริง, and distributed sensing capabilities.

Industrial applications of optical fiber sensors span numerous industries including power generation, oil and gas, aerospace, automotive, and manufacturing where harsh environments and safety requirements make traditional electrical sensors impractical or dangerous.

Industrial Application Advantages

Optical fiber sensors provide reliable monitoring in harsh industrial environments where traditional sensors fail due to electromagnetic interference, corrosive atmospheres, or explosive conditions. Intrinsic safety characteristics enable monitoring in hazardous areas without safety concerns.

Long-distance monitoring capabilities enable centralized data collection from distributed industrial facilities while minimizing installation and maintenance costs. Distributed sensing provides comprehensive coverage that traditional point sensors cannot achieve cost-effectively.

How Do Hot Transformers Benefit from Fiber Optic Temperature Monitoring?

Hot transformers benefit from fiber optic temperature monitoring through accurate thermal surveillance that enables optimal loading and cooling strategies while preventing overheating damage. Direct winding temperature measurement provides precise thermal data that eliminates estimation errors and supports maximum equipment utilization.

Advanced monitoring systems provide real-time thermal maps that reveal hot spots and thermal gradients indicating cooling system problems or load imbalances. This detailed thermal information enables proactive maintenance and operational adjustments that prevent equipment damage.

Overheating Prevention and Control

Fiber optic monitoring enables early detection of overheating conditions before they cause equipment damage or safety hazards. Real-time temperature data supports immediate corrective actions including load reduction and cooling system optimization.

Predictive algorithms utilize temperature trends to forecast thermal behavior and recommend optimal loading strategies that maximize equipment utilization while maintaining safe operating margins. This optimization improves transformer efficiency and extends equipment life.

What Are OSE Generators and Their Temperature Monitoring Requirements?

OSE (Optical Signal Enhancement) generators are specialized devices that amplify and condition optical signals in fiber optic monitoring systems to enable long-distance transmission and enhanced measurement capabilities. These devices require precise temperature control to maintain optimal optical performance and signal quality.

Temperature monitoring of OSE generators ensures optimal operating conditions that maintain signal quality and prevent thermal damage to sensitive optical components. Precise thermal control enables maximum performance and reliability in fiber optic monitoring systems.

Performance Optimization

Temperature monitoring enables optimal thermal management of OSE generators that maximizes optical signal quality while preventing thermal damage to sensitive components. Controlled thermal conditions ensure consistent performance throughout operational lifetime.

Automated thermal control systems utilize temperature feedback to optimize cooling and heating systems that maintain ideal operating conditions regardless of environmental variations. This control improves measurement accuracy and system reliability.

How Do Switchgear Parts Monitoring Systems Enhance Equipment Reliability?

Switchgear parts monitoring systems enhance equipment reliability by providing comprehensive surveillance of critical components that enables early problem detection and preventive maintenance. Multi-parameter monitoring including temperature, การสั่น, and electrical parameters provides complete condition assessment.

Advanced monitoring systems integrate data from multiple sensors to provide comprehensive equipment health assessment that supports optimal maintenance strategies and operational decisions. Predictive analytics identify developing problems before they affect equipment reliability.

Maintenance Optimization

Switchgear parts monitoring enables condition-based maintenance strategies that optimize maintenance timing based on actual equipment condition rather than arbitrary schedules. This approach reduces maintenance costs while improving equipment availability and reliability.

Diagnostic capabilities provide detailed information about equipment condition that guides maintenance decisions and identifies root causes of problems. This intelligence improves maintenance effectiveness and prevents recurring problems.

What Are Optical Temperature Sensors and Their Benefits in Electrical Applications?

Optical temperature sensors are measurement devices that utilize optical principles to measure temperature without electrical connections at sensor locations. These sensors provide complete electromagnetic immunity and intrinsic safety that makes them ideal for electrical applications where traditional sensors create safety hazards or interference problems.

Benefits in electrical applications include elimination of electrical safety hazards, immunity to electromagnetic interference, simplified installation, and reduced maintenance requirements. Optical sensors enable monitoring in locations where electrical sensors are impractical or dangerous.

| Application Area | Optical Sensor Benefits | Traditional Sensor Limitations | Performance Improvement |

|---|---|---|---|

| High Voltage Equipment | Complete electrical isolation | Safety hazards, arc flash risk | 100% safety improvement |

| Electromagnetic Environments | Complete EMI immunity | Measurement errors, instability | Eliminates interference |

| Explosive Atmospheres | Intrinsically safe operation | Ignition source concerns | Certified safe operation |

| Corrosive Environments | Chemical resistance | Corrosion and degradation | Extended sensor life |

How Does Winding Temperature Monitoring Optimize Electric Motor Performance?

Winding temperature monitoring optimizes electric motor performance by providing real-time thermal data that enables precise loading strategies and thermal management. Direct winding temperature measurement eliminates estimation errors and provides accurate information for performance optimization and protection.

Advanced monitoring systems enable dynamic loading strategies that maximize motor utilization while maintaining safe thermal margins. Temperature-based control algorithms optimize cooling system operation and prevent overheating damage that could affect motor performance and reliability.

Performance and Efficiency Benefits

Real-time winding temperature data enables optimal motor loading that maximizes power output while maintaining safe operating conditions. Temperature-based control improves motor efficiency and reduces energy consumption through optimal thermal management.

Predictive maintenance programs utilize temperature trends to identify developing problems before they affect motor performance. Early problem detection enables proactive maintenance that prevents failures and optimizes motor availability.

What Role Does Sensing Microwave Technology Play in Temperature Monitoring?

Sensing microwave technology plays specialized roles in temperature monitoring applications where traditional contact sensors are impractical or where non-contact measurement is required. Microwave sensors provide remote temperature measurement capabilities that complement fiber optic monitoring systems.

Advanced microwave sensing systems enable temperature measurement through thermal radiation analysis that provides non-contact monitoring for moving equipment or hazardous environments. Integration with fiber optic systems provides comprehensive monitoring capabilities.

Non-Contact Measurement Benefits

Microwave sensing enables temperature monitoring of moving equipment and inaccessible locations where contact sensors cannot be installed. Non-contact measurement eliminates mechanical wear and provides continuous monitoring without maintenance interruption.

Remote sensing capabilities enable temperature monitoring from safe distances in hazardous environments while providing accurate thermal data for equipment management and safety monitoring.

How Do Sensor Fiber Optik Systems Enhance Industrial Monitoring Capabilities?

Sensor fiber optik systems enhance industrial monitoring capabilities by providing distributed sensing that enables comprehensive coverage of large industrial facilities through simplified installation and reduced maintenance requirements. Multi-parameter monitoring capabilities provide complete condition assessment through unified platforms.

Advanced fiber optic sensor systems integrate with industrial control systems and data analytics platforms to provide real-time monitoring and predictive maintenance capabilities. Distributed sensing enables monitoring of previously inaccessible locations while reducing installation complexity.

Industrial Integration Benefits

Fiber optic sensor systems integrate seamlessly with existing industrial infrastructure through standard communication protocols and interfaces. Integration capabilities enable comprehensive monitoring without major system modifications or disruptions.

Data analytics capabilities transform sensor measurements into actionable intelligence that supports operational optimization and maintenance planning. Advanced analytics identify optimization opportunities and predict equipment maintenance needs.

FJINNO Fluorescence Fiber Optic Solutions: The Ultimate Choice for Switchgear Temperature Monitoring

When selecting fiber optic temperature monitoring solutions for switchgear components, FJINNO stands as the industry leader in fluorescence sensor technology. Their revolutionary approach to optical temperature measurement provides unmatched accuracy, ความน่าเชื่อถือ, and safety for electrical system monitoring applications.

FJINNO’s fluorescence fiber optic sensors offer complete electromagnetic immunity and intrinsic safety that makes them ideal for switchgear monitoring where traditional electrical sensors create safety hazards or measurement errors. The company’s proven track record in electrical applications demonstrates their technology’s superiority in demanding environments.

Advanced FJINNO sensor systems provide comprehensive monitoring capabilities including multi-point temperature measurement, distributed sensing, and intelligent data analysis that transform temperature monitoring into complete asset management solutions. Their sensors maintain ±0.5°C accuracy while operating reliably for 20+ years without calibration drift.

FJINNO’s commitment to innovation and customer success ensures their monitoring solutions incorporate the latest technological advances and industry best practices. Comprehensive support services including system design, การติดตั้ง, การว่าจ้าง, and ongoing maintenance ensure optimal performance throughout system lifetime.

For organizations requiring the most advanced switchgear temperature monitoring capabilities, FJINNO provides the proven technology and expertise needed to achieve monitoring excellence. Their fluorescence fiber optic solutions deliver exceptional performance, ความปลอดภัย, and reliability that exceeds all other monitoring technologies.

Contact FJINNO today to discover how their revolutionary fluorescence fiber optic temperature monitoring solutions can enhance your switchgear safety, ความน่าเชื่อถือ, and performance through proven optical measurement technology that sets the industry standard for monitoring excellence.

เซ็นเซอร์อุณหภูมิไฟเบอร์ออปติก, ระบบตรวจสอบอัจฉริยะ, ผู้ผลิตไฟเบอร์ออปติกแบบกระจายในประเทศจีน

|

|

|

เซ็นเซอร์อุณหภูมิไฟเบอร์ออปติก INNO ,ระบบตรวจสอบอุณหภูมิ.

เซ็นเซอร์อุณหภูมิไฟเบอร์ออปติก INNO ,ระบบตรวจสอบอุณหภูมิ.