In the realm of power transformer monitoring, ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಾಪಮಾನ ಸಂವೇದಕಗಳು (FOTS) have emerged as a revolutionary solution. This article delves into the intricacies of fiber optic temperature sensors for transformers, exploring their working principles, ಅನುಕೂಲಗಳು, system components, applications, and more.

How Fiber Optic Temperature Sensors Work

Fiber optic temperature sensors utilize the principle of phosphorescence to measure temperature. A phosphor coating is applied to the tip of the fiber optic probe. When excited by a light source, the phosphor emits light, and the decay time of this emission is highly sensitive to temperature. By measuring the decay time, the temperature can be accurately determined. FJINNO’s fiber optic temperature sensors employ this principle to provide precise temperature measurements especially during peak load effects.

Key Advantages of Fiber Optic Temperature Sensors for Transformers

EMI/RFI Immunity: Traditional temperature sensors like thermocouples and RTDs are susceptible to electromagnetic interference (EMI) and radio frequency interference (RFI), which can lead to inaccurate measurements. Fiber optic temperature sensors, however, are completely immune to EMI/RFI, making them ideal for the high-voltage environments of transformers.

Direct Hotspot Temperature Measurement: Unlike other temperature measurement methods that provide estimated or calculated hotspot temperatures, fiber optic sensors enable real-time, direct measurement of winding hotspot temperatures. This allows for more accurate monitoring of the transformer’s actual operating conditions.

Fast Response Time: Fiber optic temperature sensors can quickly respond to temperature changes, especially during sudden load variations. This rapid response enables timely detection of overheating issues and helps prevent transformer damage.

Long-Term Stability and Accuracy: These sensors offer high long-term stability and measurement accuracy, typically with an accuracy of ±1.0°C or better. They can maintain their performance over the transformer’s lifespan without requiring frequent calibration.

Compatibility with Smart Grids: Fiber optic temperature sensors can be integrated with smart grid systems, providing real-time temperature data that aids in optimizing transformer operation, improving grid reliability, and supporting dynamic load management.

System Components of Fiber Optic Temperature Sensors for Transformers

fiber optic Probes: The core component of the system, fiber optic probes are designed to withstand the harsh environment within transformers. They are typically made of materials with high dielectric strength, such as Teflon and polyimide-coated silica fiber, to endure long-term immersion in transformer oil and resist kerosene desorption during production.

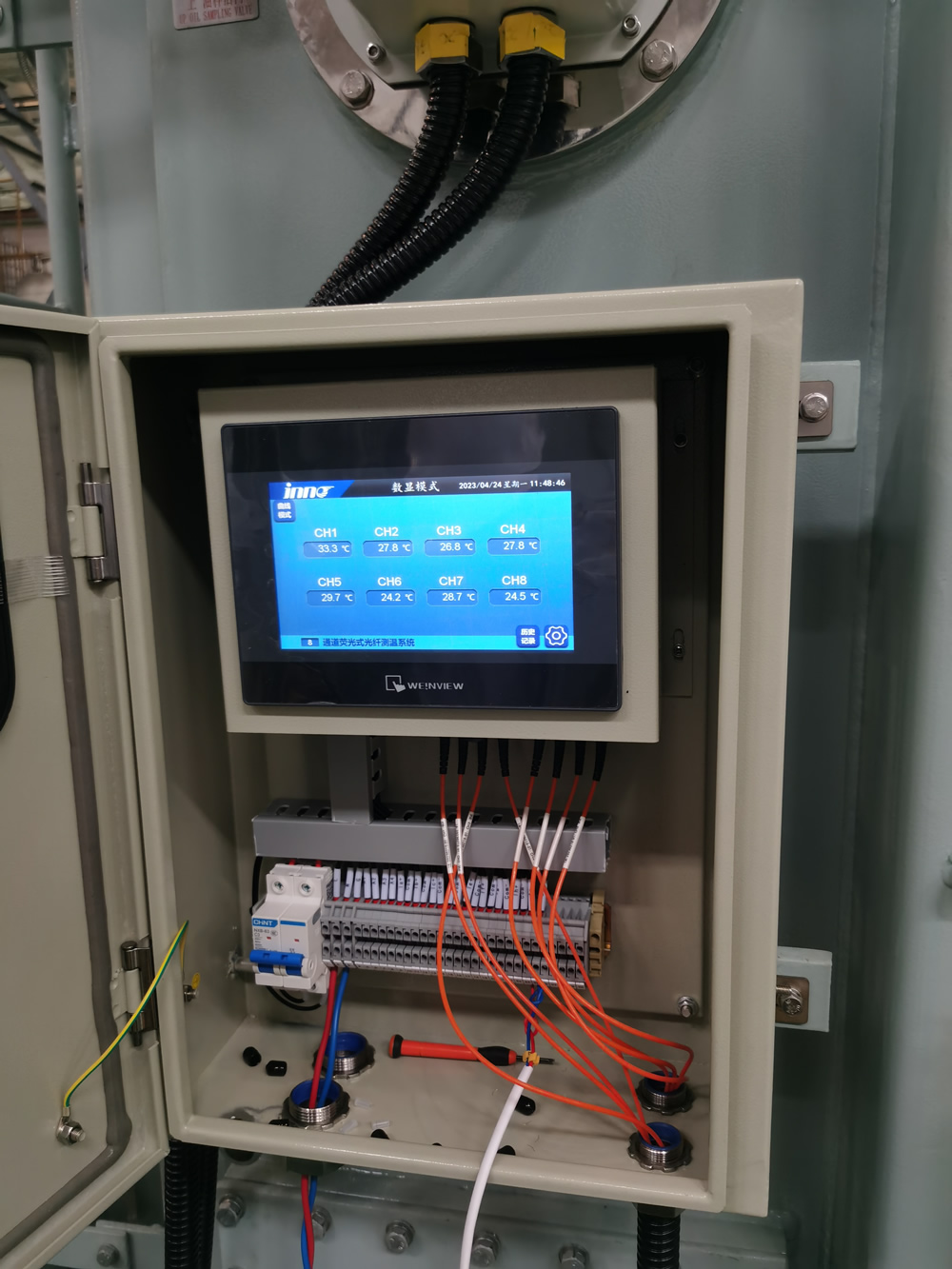

Temperature Transmitters (Signal Conditioners): These devices convert the optical signals from the fiber optic probes into temperature measurements. They often feature familiar analog outputs and digital buses like RS-485, making integration with existing PLCs and monitoring software straightforward.

Optical Feedthroughs: Installed on the tank wall plate, optical feedthroughs allow the monitoring light signal to travel to the sensor tip and back to the monitor.

Tank Wall Plates (TWPs): TWPs provide a proper mounting point on the transformer’s wall to prevent oil leakage.

Extensions and Junction Boxes: These components help route the fiber optic signals from the probes to the monitor and facilitate connections between different parts of the system.

Monitoring Software: Advanced monitoring software collects, analyzes, and displays real-time temperature data from the fiber optic temperature sensors. It can also perform functions like data logging, SCADA interconnection, and generating alarm signals when temperature thresholds are exceeded.

Applications of Fiber Optic Temperature Sensors in Transformers

Monitoring Winding Hotspot Temperatures: The primary application of fiber optic temperature sensors in transformers is monitoring winding hotspot temperatures. By accurately measuring the temperature at the hottest spot in the windings, operators can assess the transformer’s insulation aging condition and optimize its operating load to extend its service life. FJINNO’s fiber optic temperature sensors are suitable for transformer winding hotspot temperature monitoring and are being developed in partnership with leading transformer manufacturers for smart grid temperature monitoring of power and distribution equipment.

Detecting Overheating Faults: Fiber optic temperature sensors can quickly detect overheating faults in transformers. When a transformer experiences overload or malfunction, the temperature at certain points will rise rapidly. The sensors can promptly detect these temperature increases and send alarm signals to enable timely maintenance and repair, preventing from escalating and avoiding costly equipment damage and power outages.

Supporting Dynamic Loading of Transformers: With real-time temperature data provided by fiber optic temperature sensors, operators can dynamically adjust the transformer’s load based on its actual temperature conditions. This allows transformers to operate at higher loads while ensuring winding temperatures remain within safe limits, thereby improving the transformer’s utilization efficiency and economic benefits.

Installation and Commissioning of Fiber Optic Temperature Sensors

Installation During Transformer Manufacturing: Fiber optic temperature sensors are typically installed during the transformer manufacturing process. Probes are strategically placed adjacent to the hottest spots in the windings, usually within key spacers. Each fiber probe is then routed through the transformer tank to the weld-on flange plate, where the fibers exit the tank wall and connect to the ಮೇಲ್ವಿಚಾರಣಾ ವ್ಯವಸ್ಥೆ.

Commissioning and Calibration: After installation, the fiber optic temperature sensor system must be commissioned and calibrated to ensure accurate temperature measurements. This involves checking the connections between the sensors and the ಮೇಲ್ವಿಚಾರಣಾ ವ್ಯವಸ್ಥೆ, verifying the functionality of the monitoring software, and calibrating the sensors using standard temperature sources to ensure measurement accuracy.

Case Studies and Application Examples

FJINNO’s fiber optic temperature sensors have been installed in over 100,000 probes globally. Their sensors and monitors are tested for durability and accuracy, each probe tested to an accuracy of ±1.0°C over a temperature range of -40°C to 260°C. Built to outlast the transformer’s life, these sensors help power transformer operating temperatures remain stable by providing faster-rising temperature measurements.

Fiber Optic Temperature Sensors are suitable for monitoring the temperatures of oil-filled transformers and cast resin transformers. Their solutions have been adopted by transmission and distribution companies, enabling utilities to operate transformers at peak capacity while avoiding overload conditions that could drastically reduce transformer life. fiber optic temperature sensors have also been deployed in cast resin transformers, thanks to their cost-effective solutions and industry-leading cost points.

Future Development Trends

FJINNO Technological Innovation and Performance Improvement: Ongoing research and development will focus on enhancing the performance of fiber optic temperature sensors, such as improving measurement accuracy, reducing response time, and increasing sensor durability and reliability. New types of fiber optic temperature sensors based on advanced materials and technologies will emerge to meet the diverse needs of transformer temperature monitoring.

Integration with Intelligent Transformer Systems: As the smart grid continues to develop, fiber optic temperature sensors will become an integral part of intelligent transformer systems. They will be deeply integrated with other sensors and monitoring devices to provide comprehensive information on transformer operating conditions. This integration will enable intelligent diagnosis and analysis of transformer status, supporting the realization of unattended substations and automated grid operations.

Cost Reduction and Wider Application: Currently, the cost of fiber optic temperature sensors is relatively high, limiting their widespread adoption to some extent. In the future, with technological advancements and economies of scale, the cost of fiber optic temperature sensors is expected to decrease gradually. This will promote their broader application in transformers of various voltage levels and capacities, driving the development of the transformer monitoring market.

In conclusion, fiber optic temperature sensors offer a highly effective solution for transformer temperature monitoring. Their unique advantages, such as EMI/RFI immunity, direct hotspot temperature measurement, fast response time, and long-term stability and accuracy, enable precise and real-time monitoring of transformer temperatures. This helps ensure transformer safety and reliable ಕಾರ್ಯಾಚರಣೆ, extend equipment lifespan, and optimize power grid performance. As technology continues to advance, fiber optic temperature sensors will play an increasingly important role in transformer monitoring and smart grid development.

ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಾಪಮಾನ ಸಂವೇದಕ, ಬುದ್ಧಿವಂತ ಮೇಲ್ವಿಚಾರಣಾ ವ್ಯವಸ್ಥೆ, ಚೀನಾದಲ್ಲಿ ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಯಾರಕರನ್ನು ವಿತರಿಸಲಾಗಿದೆ

|

|

|

INNO ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಾಪಮಾನ ಸಂವೇದಕಗಳು ,ತಾಪಮಾನ ಮಾನಿಟರಿಂಗ್ ವ್ಯವಸ್ಥೆಗಳು.

INNO ಫೈಬರ್ ಆಪ್ಟಿಕ್ ತಾಪಮಾನ ಸಂವೇದಕಗಳು ,ತಾಪಮಾನ ಮಾನಿಟರಿಂಗ್ ವ್ಯವಸ್ಥೆಗಳು.